Danish machining company wins larger CERN tender after years of supplying many smaller orders

Since 2011, the machine factory Horsens Spån Teknik has sent new deliveries to CERN every month. Now, the company has won a larger CERN tender for a custom-designed mechatronic product.

Horsens Spån Teknik (HST) has been supplier to CERN for almost ten years. The company is specialised in supplying small series of complex components, which it has supplied to CERN for many years. Traditionally, HST has received orders below the threshold for orders that are to be tendered. But at the end of 2018, the company participated in a pre-qualification and later won the tender amounting to around 70,000 euros – a large order for the company, which employs 28 people.

- We received an inquiry on how the finished topics should look, during the pre-qualification phase. It took us a while to finish everything for the prequalification, but it was time well spent by the time we made a bid for the final offer, says Kent Petersen, sales manager at HST.

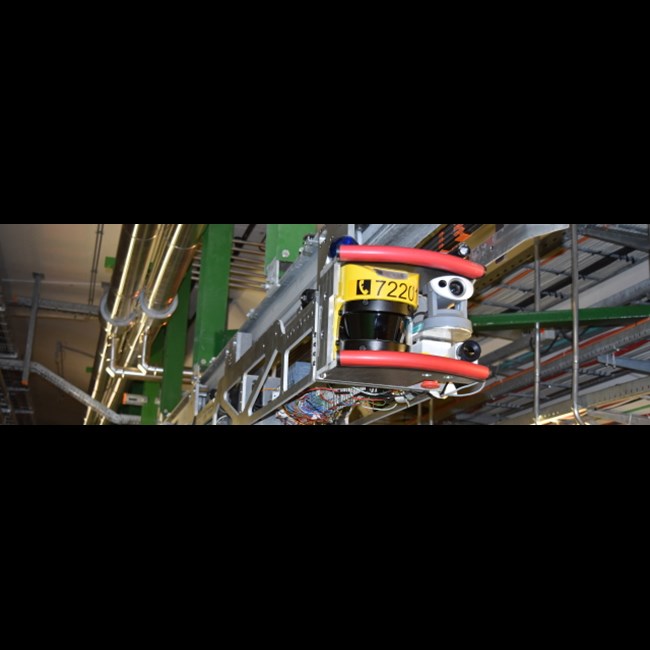

The tender included delivering items for the Train Inspection Monorail (TIM), a mechatronic product designed for CERN’s specific needs, with the goal to provide unmanned actions in the Large Hadron Collider (LHC) tunnel when there is no active beam, during beam stops and shut-downs.

Relationship-building is essential

During HST's many years as a CERN supplier, the company has prioritised visiting CERN and maintaining relations with its contacts in the purchasing and technical areas at CERN.

- I think it is essential for a company to visit its customers, especially within the Big Science industry. Our company has a good reputation at CERN, because we deliver what they demand on time, but also because we regularly visit our contacts there, says Kent Petersen.